|

The

Brooklyn Bridge

|

In the 19th century, the booming New York communities

of Brooklyn and Manhattan were divided by the East River. A

bridge was the answer, but it would require an engineering feat

such as the world had never before seen. In the end, a bridge

was erected, but at the cost of the death of its chief designer

and a life of suffering for its chief engineer..

In the middle of the winter of 1852, engineer

John Roebling found himself trapped on a ferry going between

the city of Brooklyn and Manhattan Island. The waters had frozen

solid around the boat and Roebling and his 15-year-old son,

Washington, spent hours on the vessel waiting for it to work

its way through the ice. As he sat there, the elder Roebling,

a renowned civil engineer, pondered the possibility of building

a bridge between these two bustling cities to alleviate this

problem. However erecting such a structure would be no easy

feat. The East River, which was more an arm of the sea rather

than a river, was a third of a mile wide and subject to rushing

tides and swirling hazardous waters.

John

Roebling's Dream

| Seven Quick

Facts |

| Opened: May

24th, 1883 |

| Height at Towers:

276.5 feet (84.3 m) |

| Distance between

towers: 1,595.5 feet (486.3 m) |

| Total length:

5,989 feet (1,825.4 m) |

| Design: A hybrid

cable-stayed/suspension bridge |

| Cost: $15.5

million (approximately $380 million in modern dollars) |

| Other: Longest

suspension bridge in the world when completed. |

When Roebling returned to his home in Trenton,

NJ, that winter, he began to seriously study the problem of

the East River bridge and draw up plans. Roebling, a German

immigrant, was already well known for the bridges he had built

at Pittsburgh, Cincinnati and Niagara Falls. Given his experience,

Roebling decided that the bridge at Brooklyn should be a suspension

bridge. Such a bridge could span long distances but needed only

two supports. However, the longest suspension bridge built so

far was completed in Wheeling, West Virginia in 1849. It had

a span between its towers of only around 1,000 feet. A bridge

across the East River would need a span of about 1,600 feet

between towers, more than 50% longer.

Because of this, Roebling's design called for

a bridge of spectacular dimensions. The supporting towers, built

of stone in the gothic style, would stand nearly 300 feet tall.

The roadbed of the bridge itself would be a huge 85 feet wide.

To support the Manhattan tower it would be necessary to excavate

an incredible 78 feet underwater through the muck of river bed

to the bedrock below. The whole bridge, including the approaches,

would be enormous at over a mile in length. All in all, such

a construction in the mid-19 the century would require amazing

effort.

Despite Roebling's sterling reputation, critics

were skeptical about his bridge plan. Suspension bridges were

a new design and many of them, such as one at Angers, in France,

had suffered spectacular collapses. In 1866, however, another

freeze of the river shutting down ferry service made it obvious

that something had to be done. The next year the New York Bridge

Company was formed by an act of legislature. The company appointed

Roebling as the chief engineer of the project.

|

Designer

John Roebling

|

Unfortunately, during the planning stage for the

bridge John Roebling was badly injured in an accident on June

28th 1869. He was standing on a dock surveying the location

for the bridge's Brooklyn tower when a speeding ferry hit the

wharf. Roebling's foot was crushed. Despite the amputation of

his toes, lockjaw set in and he died about a month later on

July 22nd.

Fortunately, his son, Washington, was a fully

trained engineer by then and had already assisted his father

with a bridge project, giving him an understanding of the older

man's methods. His knowledge of the East River bridge plans

was exhaustive, so the company board appointed Washington as

the new chief engineer as of August, 1869.

The

Dangerous Caissons

The first challenge in erecting the bridge was

to build the foundation for the bridge towers. Since the towers

were to be located in the river, a device called a caisson would

be used to excavate the riverbed down to the bedrock. A caisson

is a large wooden box (bigger than the tower foundation) with

an open bottom. It is lowered to the river bottom and pressurized

air is pumped into it to keep the water out.

Men can then enter the caisson through an "airlock,"

which is a closed room with doors both to the outside and inside

of the device. Workers enter the room at normal pressure, then

the outside door is closed and air is pumped in until the pressure

is equal to that inside the caisson, so the inner door can be

opened. Workers can then climb down to the bottom of the casing

and dig at the river bed under relatively dry conditions.

At the time that the Brooklyn Bridge was built,

not much was known about the effect of high pressure air on

human bodies, especially at the depths involved at the bottom

of the East River on the Manhattan side. Under pressure, nitrogen

in the air can be dissolved into liquids in the body. When the

pressure is lessened, the gas can come out of those solutions

and form bubbles in dangerous places. Often a sufferer would

be bent in two by the pain, which gives the disease its nickname:

"The Bends."

The solution to the problem is to decompress anyone

leaving the caisson very slowly so that the dissolved nitrogen

can be carried away and released into the lungs. Unfortunately,

this was unknown to scientists during the era that the bridge

was being built.

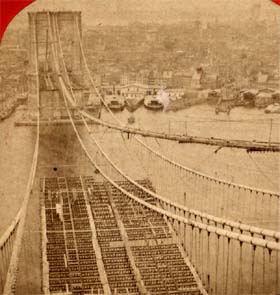

|

A

view of the bridge under construction from the top of

a tower.

|

This condition, often called "Caisson Disease,"

made working in the caissons very dangerous. Workers would seemingly

be struck with the disease randomly after they emerged from

the airlock. The symptoms varied widely from person to person

but included swollen joints, vomiting, double vision, dizziness,

paralysis and sometimes even death.

In addition to the threat of the bends, there

was also the more routine horror of working in the dark, dank

conditions of the caisson. Edmond Farrington, a master mechanic

on the project wrote:

Inside the caisson, everything wore an unreal

weird appearance. There was a confused sensation in the head…

The voice sounded faint and unnatural and it became a great

effort to speak. What with the flaming lights, deep shadows,

the confusing noise of hammers, drills and chains, the half-naked

forms flittering about … one might get a sense of Dante's inferno.

Eventually the muck of the river bed was cleared

away and concrete was poured inside the caissons to create the

foundations for the bridge's gigantic towers. While directing

this operation inside the caisson on the Manhattan side in 1872,

however, Washington Roebling himself came down with a severe

case of the bends that nearly took his life. He was taken to

his home in Brooklyn where observers did not think he would

last the night.

Even with Washington Roebling sick, construction

on the bridge, which was only about half finished, continued.

The Brooklyn tower rose first, followed by the one on the Manhattan

side. Washington, seemingly by an act of shear will, began to

recover, though he would suffer the pain of this disease for

the rest of his life.

The

Towers Rise

Through the rest of the year, the towers remained

under construction. The granite blocks, quarried in Maine, were

lifted into position by great derricks. Ninety thousand tons

of them were used in each tower. By the end of the year the

Brooklyn tower was about 140 feet high, half of its eventual

height. The Manhattan tower, likewise, was not far behind.

The next year, 1873, work began on the anchorages.

These were to tie the bridge's main cables to the ground. At

each anchorage, four 23-ton anchor plates would be buried under

tons of masonry. Each would hold one of the bridge's four cables

from moving.

|

Washington

Roebling

|

The Brooklyn Bridge is a hybrid, cable-stayed/suspension

bridge. John Roebling had designed it to be six times stronger

than necessary using two different, independent support systems.

The suspension part of the bridge worked by running four large

cables across the length of the bridge. These were anchored

on each end and held aloft by the towers. From these cables,

secondary vertical cables would be attached which ran down to

the bridge's roadbed and held its weight.

In addition to the suspension design, the Brooklyn

Bridge also used a cable-stayed system. In this design the cables

that support the roadway run up on an angle to the top of the

tower, then down the other side to another portion of the roadway.

The weight of the two sections of the roadway balance on the

tower, keeping them stable.

Making

the Steel Cables

By 1876 both the anchorages and the towers were

ready. Next, the bridge would need the cables to be put in place.

The decision was made to use the newly-invented steel wire in

the cable, something that had never been done before. A company

run by J. Lloyd Haigh was given the contract to make the cable.

Washington, whose family was also in the steel cable business,

did not trust Haigh to make a quality product and had it inspected

before it was shipped to the bridge. However, Colonel William

Paine, in charge of the inspections, began to believe that Haigh

was somehow still substituting inferior wire. Paine arranged

for his men to actually follow a wagon full of inspected wire

to the bridge and found out that it was stopping at a secret

warehouse along the way where the "good" wire was unloaded and

an inferior wire was substituted.

From then on all shipments were escorted to make

sure there were no unscheduled stops. Haigh was forced to add

150 extra wires to the cables, at his own expense, to make up

for the poor quality cable he had been using.

In the fall of 1877 they started to install the

main cables on the bridge. Each piece of steel wire was attached

to the Brooklyn anchorage, then run over the top of the two

towers and down to the Manhattan anchorage. Two hundred and

eighty of these wires were woven into a "strand" and 19 of these

strands became a cable. The cable was then bound and wrapped

with more wire. The whole process to create the four main cables

took about a year.

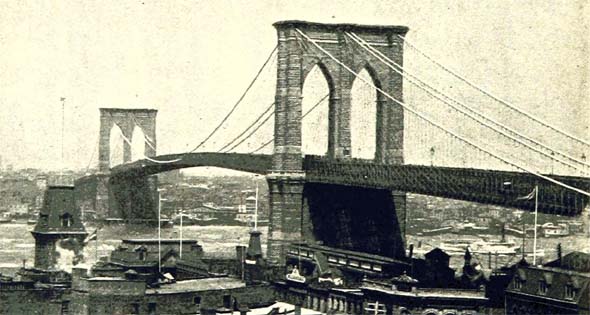

|

The

towers with a single cable in place.

|

The final portion of the project was to create

the roadbed for the bridge. Steel beams to support the roadbed

were hung from the suspender wires, which were in turn hung

from the main cables. By the end of 1878, a temporary wooden

plank path was built on top of the beams so it was possible

to actually cross the bridge on foot. This milestone was recognized

by a small celebration. Unfortunately, Washington Roebling was

still too sick to participate, but the trustees and engineers

honored Emily Roebling, his wife, by allowing her to make the

first official crossing.

Opening

of the Bridge

Unfortunately, by the time the bridge was finally

opened on May 24, 1883, Washington was still confined to his

bed. He could only watch the dignitaries at the bridge making

their speeches by telescope. Among the attendees at the ceremony

was the President of the United States, Chester A. Arthur, and

the governor of New York, Grover Cleveland. Because he could

not attend the celebration at the bridge, Washington's wife,

Emily, who had become his de facto chief assistant in the project,

arranged for a reception at their house where Washington was

congratulated by a select group of friends and dignitaries.

Within 24 hours of the bridge's opening it is

estimated that 250,000 walked across the structure. That evening

the night was filled with magnificent fireworks display and

newspapers were hailing the bridge as "the Eighth Wonder of

the World." The construction of John Roebling's vision changed

the character of New York City forever, connecting Brooklyn

and Manhattan into one urban area.

The cost of this wonder was high, however. In

addition to John Roebling's life, 27 workers perished during

the 14 years of construction. Also for the rest of his life

Washington Roebling would have to deal daily with the pain that

came from finishing his father's magnificent conception.

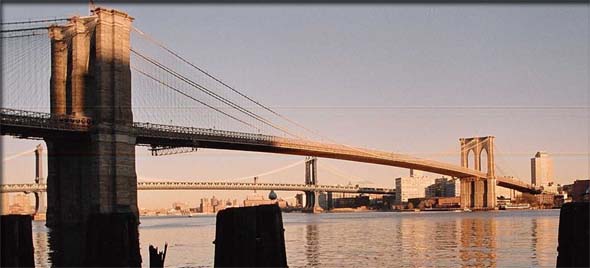

|

A

recent photo of the bridge from the Brooklyn side.

(Photo by Eduardo Manchon . Licensed under the Creative

Commons Attribution 3.0 Generic license)

|

Copyright Lee Krystek

2015. All Rights Reserved.