Notes

from the Curator's Office:

|

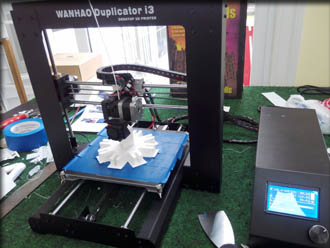

The

Wanhao Duplicator i3 working on a part for an engineering

project.

|

Fun

with a 3D Printer

(6/16)

Recently my son convinced me that the museum needed a 3D printer.

To be honest, I'd already been thinking about the usefulness

of one for a while already to fabricate art objects and various

parts. He's a mechanical engineering student and he thought

that having one might also be helpful for his senior project.

For

those not familiar with what a 3D printer is, the name is very

appropriate. A 2 dimensional printer creates things on paper

with only two dimensions - length and width. A piece of paper

can be long and wide, but for all practical purposes has no

height. As a 2D printer moves its head over the paper, it lays

down ink where needed to create a letter or an image.

A three

dimensional printer pretty much does the same thing, but can

create objects with height. A typical home three-dimensional

printer moves its print head over a bed, depositing molten plastic

onto a surface layer by layer (with each of the layers being

perhaps a millimeter high) to create something with length,

width and height. (To picture it, imagine a hot glue gun on

the end of a computer arm squeezing the glue out to create a

shape).

I put

my son in charge of making some recommendations fora good printer

and he found the Wanhao Duplicator i3. It's about $400

with mostly metal parts (many cheaper 3D printers are built

with wood). It can handle either polylactic acid (PLA) or acrylonitrile

butadiene styrene (ABS) plastic. This makes it a little more

flexible than the cheapest 3D printer, but also more expensive.

To print ABS, a printer needs a heated bed (the place where

the printer deposits the plastic), because ABS tends to shrink

when it cools and its necessary to keep the material as warm

as possible while the printing process is ongoing. Cheaper printers

do not have heated beds, which limit them to printing only PLA.

PLA is great material for most projects, but does have some

limitations. For example, it does not do as well if placed outside

and it's not as strong or flexible as ABS.

|

The

original broken knob and the replacement before painting.

|

The

Duplicator i3 arrived in a large box a few days after we ordered

it. My son assembled it in about an hour and it was ready for

testing. There are two ways to control a 3D printer. The first

is to connect it to a computer with a cable and then use software

on the computer to control the action of the printer. This works,

but means you need to keep your computer running while the printer

is operating. Since a large print job can easily run 12 hours

or more, this means your computer has to be on that entire time.

While you can typically do other stuff on your computer at the

same time it handles the printer, it also means that you can't

stop or reboot your computer without bringing the print job

to a premature end.

A much

easier way to control the printer is to have the computer write

a file containing the print instructions onto a memory chip,

then take that chip and plug it into the printer and let the

printer get the instructions off the chip. The Duplicator i3

uses a micro SD card for this. In fact, it came with a micro

SD card on which a file you can test print is already installed.

Using a small bit of PLA that came with the printer and the

file on the card, we were soon able to try out our new toy by

creating a small model of a hand giving the "OK" sign in yellow

plastic.

At first

t he printer is mesmerizing to watch. It consists of a flat

bed, perhaps 10 inches square, that can move from the front

of the printer to the back and vice versa. On either side of

the bed are two support columns, each a little more than a foot

high with a bridge at the top connecting them perhaps a foot

above the bed. There is also another bridge between the supports

that can move up and down. On the bottom of this second bridge

is the print head. It can run left and right the full length

of the bed. Since the arrangement covers all 3 dimensions, the

print head can be positioned over the bed at every location

and height in about a 10 inch cubic area.

|

An

early test of Bryce with the printer: the idea and the

reality it created.

|

As it

works, it chugs along building layer after layer of whatever

object you choose. At first it can be hard to tell what it's

making, but as you watch it slowly brings whatever you created

into existence within this 10-inch cube.

The

plastic to make the object comes in the form of filament that

looks a lot like the stuff you use in your weedwacker. A standard

spool weighs 2.2 pounds (1 kilogram) and is attached to a pylon

on top of the printer's unmoving top bridge. As the printer

uses the filament, it unspools and is sucked into the print

head where it is melted and excreted out under the direction

of the file of computer instructions.

Because

it can move the print head anywhere on the bed, in theory the

printer can print any shape you can imagine. However, there

are some practical limitations. For example, it can't start

a print in mid-air. This means that if the object you are printing

has large areas that overhang, the printer must put in supports

under that part of the print. Usually this looks like a thin

scaffolding. These supports can be somewhat problematic as they

can make a bottom section of the object that should be smooth

or detailed look rough once the supports are broken off. (One

of the first things I built was a model of the Millennium Falcon

that I downloaded from the web. The top looked nice, but most

of the bottom was rough and bumpy from supports).

Some

printers solve this problem by printing two types of plastics.

The supports are built with a type of material that is easily

dissolved and washed away, leaving just the model. However,

such printers tend to be much more expensive.

|

The

TARDIS printed from plans downloaded off the web.

|

There

is a large number of designs for objects that people have created

and uploaded onto the web at sites like http://www.thingiverse.com/.

This means that for many common objects, you don't need to do

the designing yourself. I own an HO train platform and as a

gag wanted to put a scaled-sized TARDIS (from the long running

British TV show Dr. Who) on it. I had looked around for one

the right size, without success. However, as soon as I had the

printer working I was able to find a model of the TARDIS online,

download it, scale it to the right size and print it. I only

needed to paint it the proper blue color before placing it on

my train platform.

While

there are a zillion items you can download and print, perhaps

the best satisfaction from the machine comes from designing

your own objects and printing them. For many years I've done

computer 3D art using such programs as Bryce and Daz Studio.

While I could produce interesting pictures with this software,

the printer now allows me to produce real objects.

One

of the first things I designed and made, however, was a simple

knob. A friend of my wife's had an older Subaru and the knob

that controlled the hot/cold for the ventilation system had

broken off. The price for a new one from the dealer was around

$38. It occurred to me I could just design and print one. With

30 minutes of software work and an hour of printing, it was

done. After a little black paint I was able to install it into

her car and she no longer needs me to come out with a pair of

pliers every season to switch the mode on her heater.

My first

large project was a ray gun. It's part of an art piece based

on H.G. Well's War

of the Worlds. It was designed using Bryce and consists

of six parts printed separately. By designing a larger object

as multiple pieces and printing them separately, you can make

the object larger than the print bed can hold. This approach

also keeps the printing times down and allows you to orient

each piece when printed to avoid as many supports (and the problems

associated with the bumpy surface they leave) as possible.

While

you could probably construct a ray gun using more standard techniques,

the use of the computer and printer allow you almost complete

freedom in design. For example, the ray gun is designed to be

held by a Martian tentacle and the grip as an indented spiral.

While this would be difficult to make with regular tools, the

printer can construct it just as easy as any other shape.

|

The

ray gun as individual parts before assembly.

|

While

today the Wanhao Duplicator i3 and other similar printers are

more of a hobbit's toy than a consumer product (they require

fairly regular alignment and maintenance), it isn't hard to

imagine a day a decade or two from now where a wide variety

of objects could be printed by simply downloading the plans

from a computer and letting the device create it.

If you

don't want to wait that long, there are certainly a number of

3D printers out there you can buy and experiment with. While

I found the Wanhao Duplicator i3 a great product, it is possible

to get 3D printers for as low as $200 (though you would be limited

to printing PLA). There are also more expensive printers which

give you such options as more speed and an enclosed printing

space (this can be a useful safety option if you have kids as

the heat involved in melting the plastic is significant, usually

over 300 degrees Fahrenheit).

While

I used Bryce as my design software because I already owned it

and was familiar with it, there are other 3D programs such as

Autodesk 123D Design, Tinkercad and FreeCAD

that can also do the job. Many of them are free. In addition

to a design tool you will need a program called a slicer.

The slicer takes the file containing the 3D object you create

with the design program and creates another file with a set

of instructions (gcode) that the printer can follow to build

your object (It's called a slicer because it slices the model

up into many levels that the printer will create one at a time).

The slicer program can also rotate and scale the object as well

as give you an estimate on how long it will take to print it

and how much filament it will use. An example of a free slicer

program is Cura.

A standard

reel of plastic (ABS or PLA) runs about $20 on Amazon and you

can make a lot of objects with 2.2 pounds of plastic (The slicer

software usually makes the objects hollow with just a crosshatching

inside to give it strength). Even large objects rarely cost

more than a dime in terms of materials. The plastics come in

various colors (and also glow-in-the-dark), though I usually

paint my creations. PLA is naturally clear (and you can buy

it that way) but because the printer lays down one slice at

a time you can't really make anything that is perfectly clear

like glass with it, however. Such an object would be translucent.

|

The

gun in its final version.

|

If you

want to spend some more money you can get PLA which is mixed

with particles of copper, bronze or even wood. While the resulting

object made from these materials may look like those substances,

and can even be polished, they do not have the strength of those

materials, however.

Even

if you don't want to create an object from scratch, there are

thousands of objects other people have designed and place online

for download. So whether you are hankering for a statue of Cthulhu

or a model of the rocket from TV show Fireball XL-5, it can

be yours for pennies with your 3D printer.

Copyright

Lee Krystek 2016. All Rights Reserved.